THE MANUFACTURING PROCESS OF TECHNICAL TEXTILES IN DETAIL

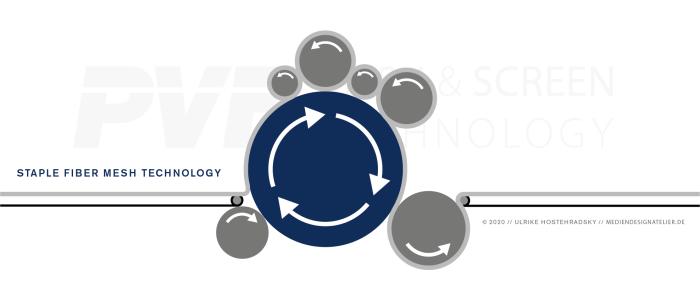

Staple-fiber mesh

For technical textiles with variable area grammage and high elasticity. The fibers are split and mixed before processing. The mesh formation is done on carding machines with rotating rollers. To achieve a high area grammage traverse layers are used. Based on the application a wide range of raw materials can be processed, for example synthetic fibers including viscose as well as natural, glass and carbon fibers.

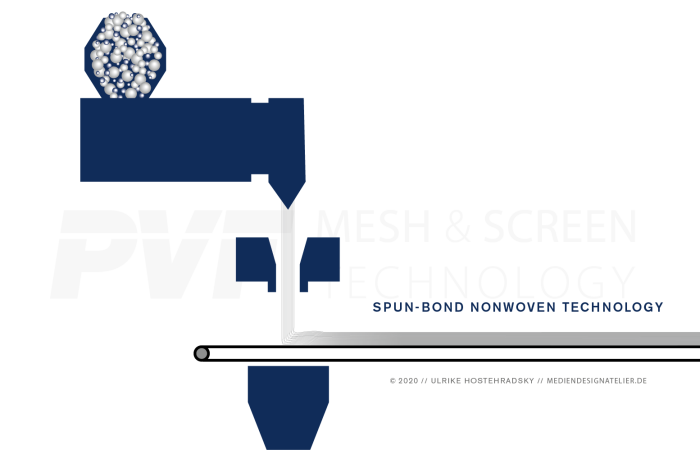

Spun-bond nonwovens

In contrast to the staple fiber felt technology, the first step of fiber spinning is left out.

Typical for this production method is the extrusion of synthetic polymers as granules of various geometry. The molten polymers, mainly polypropylene, polyester of polyethylene are spun into endless filaments by spinnerets.

In a continuous process these endless filaments are air-cooled underneath the spinnerets, stretched and laid upon a collecting belt. The spinning speed depends on the material and has an influence on quality features such as titer, stability, shrinkage and elongation.

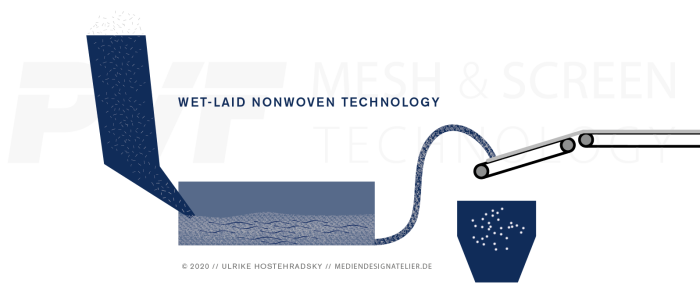

Wet-laid nonwovens

For the production staple fibers at a maximum length of 12 mm are finely atomized in large water tanks, mostly adding viscose or wood pulp. After that the compound is pumped and continuously deposited on an inclined screen. The extracted and filtered water gets recycled back into the process.

Used are synthetic fibers as well as carbon, class and ceramic fibers. To distinguish wet-laid nonwovens from wet-laid papers fibrous content by mass and diameter ratio are considered. The diameter ratio λ is the ratio of test part height h to the smallest radius of gyration of its basic surface.

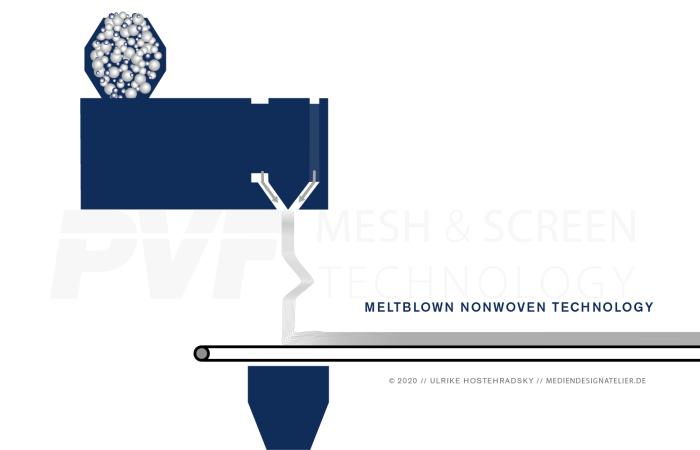

Meltblown (melt-spinning) nonwovens

Finest, meltblown microfibers for different applications.

The meltblown process is similar to the spun-bond technology. A hot gas stream blows with high velocity at the tip of the spinnerets round the molten, extruded polymer. Underneath the spinneret the filaments are stretched by the turbulent hot gas stream from a approx. 500 micrometers to approx. 1 micrometer before they finally land on the collecting belt.

Different from the spun-bond technology the throughput capacity through the individual spinnerets is very low and the required molten flow index (MFI value) of the polymer is very high, so that extra-fine fibers can be spun.

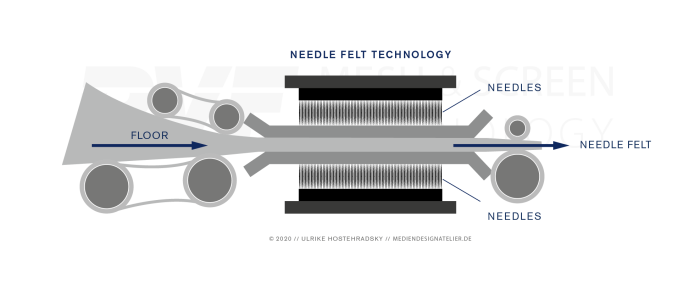

NEEDLE FELTS

Based on the material requirements, various compositions of the pile used for the production of needle felt are possible considering the individual specifications and proportions.

During the needling process for more tightness, the fibres are formed to fibre bundles.

The connection of the bundles results in a solid needle felt.

Depending on the customer’s requirement our nonwovens can be thermally bonded in the process of manufacturing.